▼

The diversified capabilities of GomunoInaki's

Technical Department supports the needs of our customers.

"Just submit our drawings to GomunoInaki, and they'll handle the rest."

This is how GomunoInaki responds to our customers' expectations. GomunoInaki's Technical Department covers

CAE product design, Material Development, Production Process Design, and Die Design, supported by our R & D Center and Mold Research Center.

GomunoInaki is working to develop new discoveries to support our customers.

In order to facilitate fast and accurate data transfer with our customers, various 3D CAD systems are utilized.

These systems include three-dimensional model data creation from 2D drawings, creations of mold data in CAM,

high-speed molding data in STL (Stereo Lithography), along with various molding related products are available to the customer.

| Category | Equipment | Make | Model | Quantity |

|---|---|---|---|---|

| CAD/CAM | 3D CAM system | JBM | Master CAM X3 | 1 |

| 3D CAD/CAM system | ISID | UNIGRPHICS NX5 | 1 | |

| Machine tool | Machining center | YASDA | YBM-950V | 1 |

| Wire-electric discharge machine | Sodick | AG600L | 1 | |

| Composite NC lathe with No.2 Y-axis | Mazak | INTEGREX200 Ⅳ-T | 1 | |

| Vibration testing | Electromagnetic vibration testing machine with chamber | IMV | EM2301 | 1 |

| Hydraulic fatigue tester with chamber | Shimadzu | EHF-UB50kN-40L | 1 | |

| Torsional testing machine | Shimadzu | EHF-TV02KNM-040 | 1 | |

| Seal testing | Air leak tester | Cosmo | LS-900 | 1 |

| Low temperature tester | Automatic T-R tester | Ueshima | TM-3531 | 1 |

| Fluidity tester | Mooney viscosity tester | Toyo Seiki | AM-1PM | 1 |

| Rheometer (Lotus vulcanization testing) | Toyo Seiki | RLR-3 | 1 | |

| Capillary rheometer | Toyo Seiki | 1D | 1 | |

| Material property testing | Durometer A | Shimadzu | 2 | |

| Wallace micro-hardness testers | Wallace | H-12 | 2 | |

| Teclock micro-hardness tester | Teclock | GS-680 | 1 | |

| Autograph | Shimadzu | AGS-500B | 1 | |

| Dispersion measurement machine | OPTIGRADE | dispergrader1000 | 1 | |

| Characteristics | De Mattia flex cracking tester with.chamber | Toyo Seiki | G7A-L | 1 |

| Thermal shock chamber | ETAC | NT510 | 1 | |

| Ozone weather meter | SUGA | OMS-LX | 2 | |

| Microammeter | ADC | 5450 | 1 | |

| Oven | Test tube aging testers | Toyo Seiki | UT15 | 3 |

| Thermostatic chamber (Maximum temperature: 500℃) |

espec | STPH-200 | 1 | |

| Material processing | Test roll mill | Kansai Roll | 8in | 1 |

| Test kneader machine | Toshin | 3L | 1 | |

| 3D-CAD | CATIA V5 | Dassault | R23 | 2 |

| SolidWorks | Dassault | Ver2015 | 2 | |

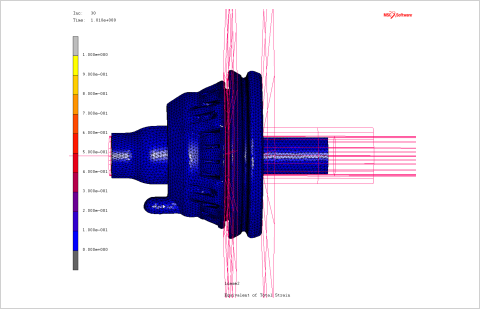

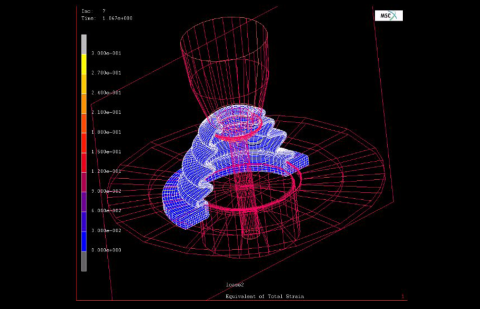

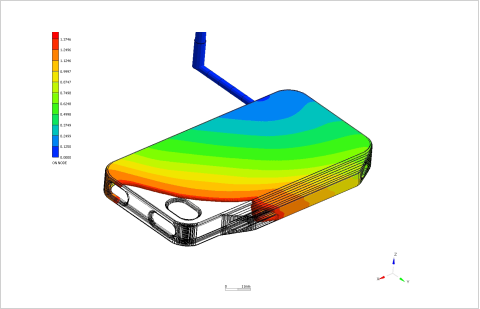

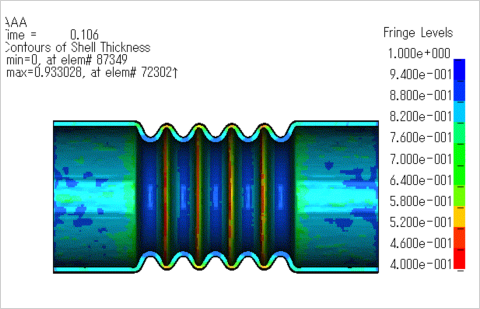

| CAE | 3D-TIMON (Fluidity analysis) | Toray Eengineering | 3D TIMON Ver10 R2.4 | 1 |

| Marc (Nonlinear structure analysis) | MSC | MARC Ver2012 | 1 |